Modules

Webcasts

- 20 Steps to a Reliable Mobile Phase - Q & A

- CHROMtalks - Fundamentals and Principles of Extra Column Band Broadening in UHPLC: A Tutorial

- The Rights and Wrongs of Mobile Phase Preparation Q&A

- The Rights and Wrongs of Mobile Phase Preparation

- Top 10 Tips for Selecting HPLC Column Chemistry and Dimensions

- + VIEW MORE WEBCASTS

Video Courses

Modules

Webcasts

- Leveraging Optimal Performance of Charged Aerosol Detection Through Optimization and Troubleshooting Techniques

- Everything You Need to Know About UV Detectors for HPLC

- HPLC Detectors – What, Where, When, and How

- Everything You Should Know About UV Detection for HPLC

- Tips and Tricks for Carbohydrate Analysis Using HPAE-PAD

- + VIEW MORE WEBCASTS

Webcasts

- Troubleshooting HPLC Mobile Phase Issues - Q&A

- CHROMtalks - The Top Seven Autosampler Problems and How to Avoid Them

- CHROMtalks - Listen to Your LC Instrument - It Is Trying to Tell You Something!

- CHROMtalks - Essentials of LC Troubleshooting - Some Problems Just Never Go Away

- Troubleshooting Sensitivity Issues (HPLC-UV)

- + VIEW MORE WEBCASTS

Modules

Webcasts

- CHROMtalks - Beyond the HPLC Column: Understanding Non-Column Factors That Influence Peak Widths and Shapes in High-Efficiency Separations

- CHROMtalks - A Generic Methodology for Streamlined Performance Monitoring of a Wide Range of Reversed Phase UHPLC Columns Over Time

- CHROMtalks - The Selectivity Landscape in Reversed-Phase LC—Using Selectivity Models to Find Columns that Are Similar, or Different

- Developing Better Methods for Reversed Phase HPLC

- Translating and Transferring HPLC Methods

- + VIEW MORE WEBCASTS

Video Courses

Modules

Modules

Modules

Webcasts

- Principles of Operation, Maintenance, and Troubleshooting for Sulfur and Nitrogen Chemiluminescence Detectors with Gas Chromatography

- CHROMtalks - GC Sample Introduction - The Achilles Heel of GC

- CHROMtalks - Qualifying and Optimizing GC Instruments and Methods in High-Throughput Regulated Laboratories

- CHROMtalks - Detecting It All - Keeping Your Response Consistent with Common GC Detectors

- CHROMtalks - Optimizing the Inlet-to-Column Transition in Gas Chromatography

- + VIEW MORE WEBCASTS

Webcasts

- CHROMtalks - Troubleshooting GC Sample Introduction

- CHROMtalks - GC Troubleshooting in Five Simple Pictures

- CHROMtalks - Hidden Errors and Mistakes that Make Your GC Results Look Better than They Really Are

- GC Troubleshooting - Gas Supply and Inlet Issues

- GC Troubleshooting in 20 Pictures - Part I

- + VIEW MORE WEBCASTS

Webcasts

- CHROMtalks - GCxGC: It’s Not That Hard - Really!

- CHROMtalks - GC Column Selection: The Three Most Important Parameters to Consider

- Automated Derivatization for Gas Chromatography

- A More Cost-Effective Carrier Gas for Volatile Organic Compound Analysis

- Air Monitoring: What are the Right Tools for the Job?

- + VIEW MORE WEBCASTS

Video Courses

Modules

Modules

Webcasts

- CHROMTalks Sample Preparation Series

- Everything You Need to Know About Filtration

- Troubleshooting Sample Preparation: Filtration, LLE, SLE, and SPE

- Improved Speed of Extractables Studies Using Accelerated Solvent Extraction and LC-MS

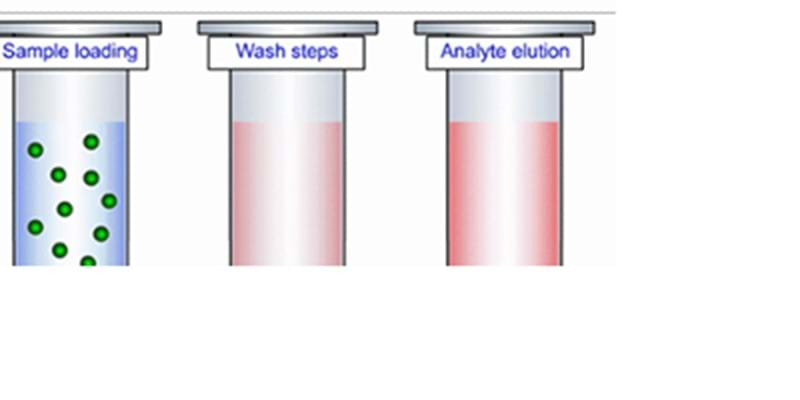

- Understanding the Mechanisms of Solid Phase Extraction

- + VIEW MORE WEBCASTS

Quick Guides

Modules

Webcasts

Video Courses

Video Courses

Webcasts

Webcasts

Modules

Modules

Webcasts

Modules

Quick Guides

Webcasts

- Native and Denaturing Mode Size Exclusion Analysis of Biotherapeutics

- N-Glycan Sample Prep and Analysis Workflows for Screening and Characterization of Biotherapeutics

- Purification and Analysis of Synthetic Peptides: The Challenges of Method Development

- The Power of LC-MS in the Characterization of Protein Biopharmaceuticals

- The Analysis of Post-Translational Modifications Using LC-MS/MS

- + VIEW MORE WEBCASTS

Quick Guides

- Demystifying Reversed Phase Column Selection for Biomolecule Analysis

- First Steps in Characterizing Biotherapeutics

- Reversed Phase HPLC for the Analysis of Biomolecules

- HILIC, IEX, and SEC for the Analysis of Biomolecules

- Selecting Columns and Initial Conditions for IEX and SEC Biomolecule Analysis

- + VIEW MORE GUIDES

Webcasts

- HPLC Analysis of Oligonucleotides

- LC/MS MAM Analysis of Adeno-Associated Virus Particles

- CHROMtalks - Tips and Tricks for Contemporary LC Separations of Biomolecules

- In-depth Characterization of Biopharmaceuticals by Multidimensional LC-MS

- Tips to Optimize Lab Scale Oligonucleotide Purification

- + VIEW MORE WEBCASTS

Webcasts

- From Struggles to Solutions: Strategies for Overcoming Oligonucleotide Challenges

- Oligonucleotide Symposium: Solutions to Analytical Challenges, CMC Factors, and Compliance Considerations in Biopharmaceutical Manufacturing

- N-Glycan Separations: How HILIC Columns Affect Data Quality

- Method Development Optimization from Characterization to Purification of Oligonucleotides

Webcasts

Modules